A simpler MMU extruder (part 1?)

Context

I finally finished building my first fast 3d printer (voron 0.2) and it’s time to think about getting the next hot thing: a multi-material system. If you are not aware about the context, a MMU system allows your normal 3D printer to print the same part with 2 (or more) different filaments.

Very (extremely) roughly speaking, there are two generations of systems in the DYI market:

CAM mechanism

All filament lanes are driven by a single extruder. However, there’s an additional servo motor per each lane which engages a speficic lane. All lanes are disengaged when you start printing (until the next filament change).

Example #1: Pico-MMU

Example #2: ERCF

Slightly more complex, but the general idea is the same.

Advantages:

- When you start printing, MMU acts as if it’s not there (the MMU extruder is not engaged)

Disadvantages:

- Requires high dimentional accuracy and tuned clearances for printed parts.

- Requires precise tuning to work.

- High complexity and number of parts.

Just to be clear, those systems work amazing. However, let’s imagine you print with 0.2mm layer high and with 4 colors in each layer. Let’s imagine that you print 120mm height every 5 hours. If you want your printer to successfully print 1000 hours, your failure rate has to be less than 1 in 480000. The more moving parts you have, the harder it is to achieve. Also, every single assembly error matters here.

Synced extruders

Example #1: BoxTurtle

Example #2: NightOwl / Infinite Spool System

The Primitive Infinite Spool system has an amazing summary of this. Your MMU extruder and your printer extruder movein sync (they don’t have to be perfectly in sync if you have something like a Belay sensor).

Advantages:

- Much, much simpler and far fewer moving parts.

Disadvantages:

- Precise extruder sync calibration is needed

- Belay sensor is needed

- Overconstrained filament moving might (theoretically) cause print quality issues.

A mixed approach?

I was thinking whether I could make an even simpler system. What if we combine the both approaches?

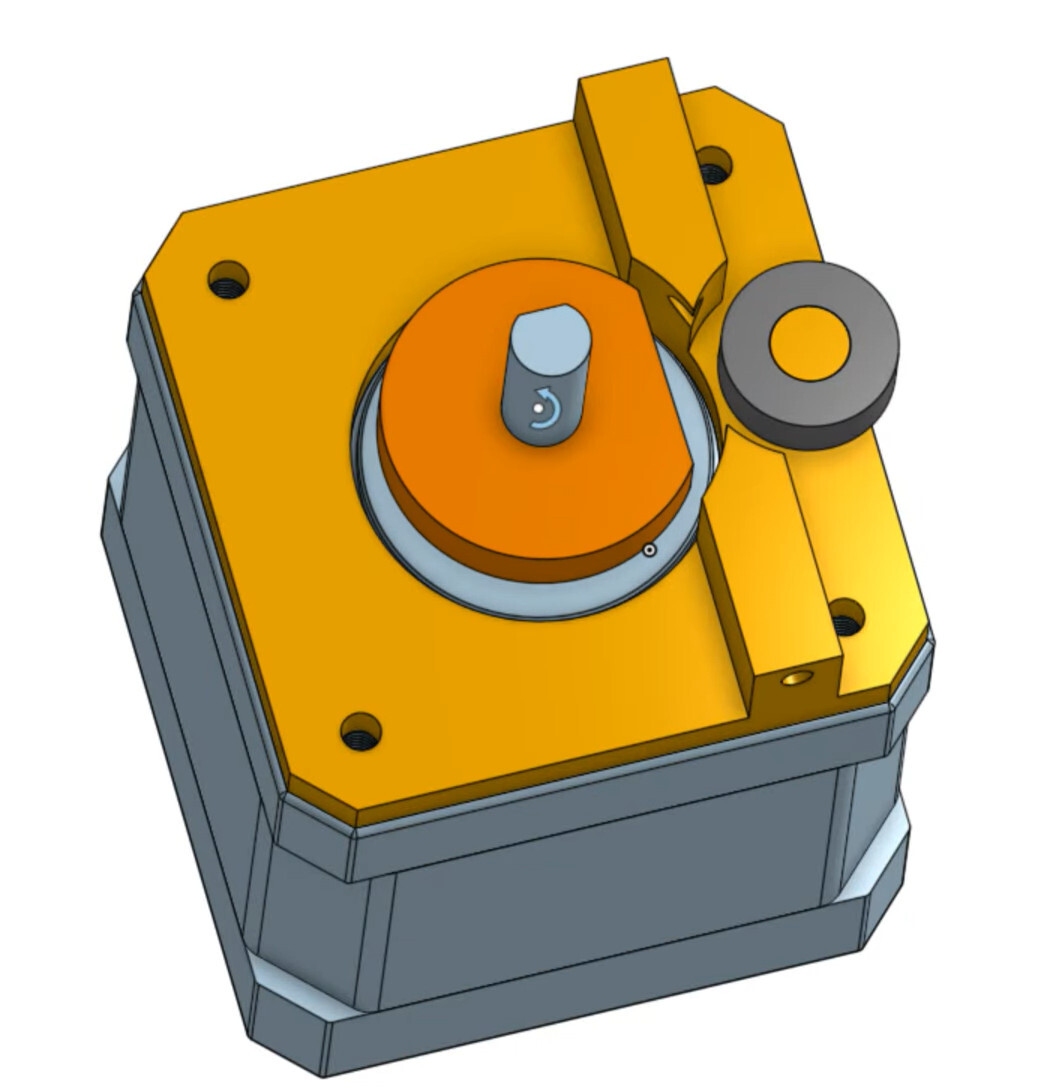

Imagine that if the filament drive gear also has a CAM inside it. The video shows a super simplified model, won’t work as it obviously:

When the drive gear rotates, filament can can be pushed both ways (with some skips, but they are not critical since we are not currently printing, just changing the active lane).

When the drive gear parks in a specific spot, the filament is free to move in both directions and is completely controlled by the direct drive extruder.

Advantages:

- Combines advantages of two other approaches, with almost none of their disadvanatges

Disadvantages:

- You have to know the location of your extruder (basically the park angle).

Other improvements I had in mind

When making the first prototype, I also want to try to use the following changes over the current designs:

- Moving filament with belts, like Proper Extruder. Theoretically speaking, when you don’t leave extra gear marks on your filament, you improve quality.

- If moving with the belt works, it could also remove the need for the spring-based filament tension. This is usually needed to not overtighen the filament between two metal parts. When using belts, it might not be necessary, since the belt itself will be springy. Needs testing ofc.

- Moving filaments without any extra gear reduction steps. From my understanding, usually it’s done to increase motor torque. I think in MMU we are mostly interested in moving speed. Not sure, needs testing.

Next steps

It works in CAD, but it’s time to start printing some prototypes :) I will try to write a separate blog post with an update, even if this does not work for one reason or another.